Experimental Analysis PVP Coated Silver Nanofluid Properties for Application in Photovoltaic/Thermal (PVT) Collectors

Abstract

Nowadays, supplying energy for the global population has turned into a prominent issue for countries engendering the consumption of huge amounts of fossil fuels which leads to some serious environmental problems. Among the renewable energy technologies, solar collectors can play major role to improve the efficiency, in air conditioning utility systems by minimum pollution. In photovoltaic/thermal (PVT) solar collectors, which are currently considered as the most advanced type to produce electricity and heat simultaneously, working fluid absorbs Energy from photovoltaic (PV) module engendering to decrease temperature of PV module and increase the electricity efficiency and also provide permissible amount of heat for other residential applications. Meanwhile, utilizing nanofluid as the working fluid in collector, regarding that the nanofluid has enhanced thermal properties relative to the base fluid, leads to a higher collector efficiency. In this research, PVP coated silver nanofluid was prepared in three volume concentration being 250, 500 and 1000 ppm by two-step method. To assess the stability of nanofluid the zeta potential is calculated which is obtained -41.6 V. Also, the prominent thermal properties of the nanofluid were analyzed regarding PVT solar collector applications. According to the results, thermal conductivity of the PVP coated silver nanofluid, improves the properties of base fluid, to the extent that thermal conductivity coefficient grows up 50% in some temperatures and increased from 0.594 for base fluid to 1.098 W/mK by escalation of concentration to 1000 ppm. Thus, PVP coated silver nanofluid can be deemed as the vital working fluid to improve the performance of PVT solar collectors.

Author Contributions

Academic Editor: Xuelai Zhang,

Checked for plagiarism: Yes

Review by: Single-blind

Copyright © 2020 A. Naderi, et al.

This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

This is an open-access article distributed under the terms of the Creative Commons Attribution License, which permits unrestricted use, distribution, and reproduction in any medium, provided the original author and source are credited.

Competing interests

The authors have declared that no competing interests exist.

Citation:

Introduction

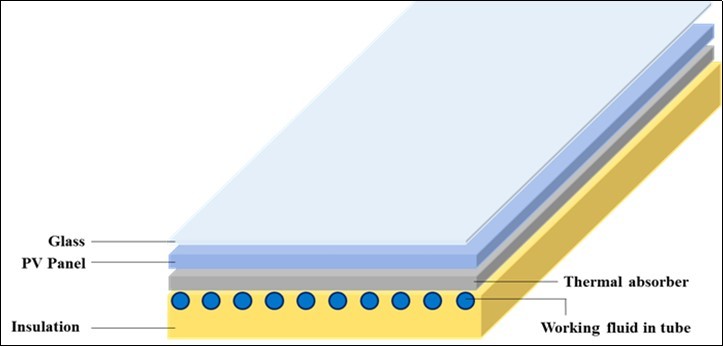

The growth of global population and the ascending trend of energy needs in societies, as well as the limitations and problems of existing energy resources, the use of renewable energy can be deemed as a vital issue for researchers. Because of the availability in most parts of the world and its capability to be provided without any environmental pollution, solar energy is a substantial alternative for fossil fuels rather than other sources of renewable energy, such as wind, water, and biomass. Meanwhile, the use of photovoltaic/thermal (PVT) solar collectors to supply thermal and electrical energy simultaneously would be a significant component in installation systems 1. PVT solar collectors (Figure 1) includes two main parts being an electric panel and a heat absorber, which convert solar radiation into electrical and thermal energy at the same time 2. Due to the structure of this type of collectors, the working fluid moving on the back side of the photovoltaic panels, absorbs thermal energy from the photovoltaic (PV) panel that reduces the surface temperature of the PV panel rising its electrical efficiency. The working fluid which gained the extra heat from PV panel, can be utilized for diverse purposes such as solar dryers and heating the water consumption 3, 4. Therefore, the thermal properties of the working fluid are considered prominent issue which should be studied. The enhancement of thermal conductivity engendering to more heat is dissipated from the photovoltaic panel and more energy is obtained by working fluid. Also, in recent years, with the advancement of nanotechnology, numerous researchers have studied the use of nanofluids to improve heat transfer in engineering applications 5, 6, 7, 8, 9, 10. Thus, by application of the properties of nanofluids in PVT solar collectors, the performance of this solar system can be improved.

Figure 1.Schematic of a sample of photovoltaic/thermal (PVT) solar collector

The main step in using nanofluids as the working fluid in PVT solar collectors is to examine the properties of them. Stability, thermal properties and radiant properties that should be considered for any nanofluid. Khan et al. review some significant researches about the properties of diverse nanofluids and determine the effect of some parameters such as particle size on the performance of them 11. Over the past decade, many researches have been done on the properties of nanofluids for use in solar collectors 12. In separate studies, Karami et al. examined the properties of nanofluids containing carbon nanotubes, carbon Nano-balls and copper oxide. They found that the above-mentioned nanoparticles can improve the radiant and thermal properties of the base fluid significantly 13, 14, 15. Vakili et al studied the effect of using nanofluid containing graphene nano-plates in direct absorption solar collectors, experimentally. They found adding nanoparticles ascends the adsorption and extinction coefficient of base fluid 16. Milanese et al. studied the optical properties of three nanofluids containing ZnO, Fe2O3 and Se2O for use in thermal systems at high temperatures. They concluded that the adsorption capacity of nanoscale grows at higher temperatures 17. Menbary et al. showed that some parameters such as PH, surfactant and duration use of ultrasonic device can affect the radiant properties of nanofluids 18. Otanicar and Golden, researched on the environmental and economic impacts of applying nanfluids in solar collectors 19.

Akhtar et al. researched on thermal conductivity and viscosity of TiO2/MWCNTs- ethylene glycol based nanofluids and reported that thermal conductivity and viscosity have opposite behavior by the rise of temperature 20. Moreover, Sakinah Muhamad Hisham et al. operated same researches on Hybrid Nanocellulose/Copper (II) Oxide Nanolubricant and reported same corollaries 21

The capability of producing thermal and electrical energy at the same time, is an instrumental feature of PVT collectors which leads some of researchers to study more in this field. Aste et al. evaluated the performance of PVT air collectors as a proper solar system in buildings, theoretically and experimentally 22. Also, they analyzed PVT water collectors and compared with common PV collectors in another study 23.

Lee et al. examined the impact of CuO/water and Al2O3/water nanofluids on electrical and thermal efficiency of PVT collectors. Based on the results, although, nanofluids have intangible effects on the electrical efficiency, thermal efficiency grows 21.3 and 15.4% by using CuO/water and Al2O3/water respectively. They also reported that the performance of studied collector at 3lit/min would be optimum 24. Despite of this research’s corollary, two other studies reported that using the Multiwalled Carbon Nanotube Nanoscale (MWCNT) enhance the electrical efficiency noticeably 25, 26. Razali et al. illustrated that, the output power of PVT solar collectors can be escalated by use of MWCNT 27. Also, the performance of PVT collectors with MWCNT-water nanofluid is analyzed with COMSOL software and an indoor experimental setup by Fayaz et al. 26. According to their numerical analysis, by applying MWCNT-water nanofluid with 0.75% volume concentration, electrical and thermal efficiency rises 10.72 and 5.62%, respectively.

Evola and Marletta found that there is an optimized temperature of inlet water for descending heat losses from collector in different circumstances 27. Jia et al. studied the performance of PVT collectors with different volume concentration of Al2O3/water and TiO2/water nanofluids. They showed that, by Al2O3/water nanofluids, the electrical and thermal power would be higher. They also reported that the thermal power of collector with 0.03 kg/s flowrate is 12.11 % more than 0.0005 kg/s flowrate 28.

Al-Waeli et al. investigated a technoeconomic evaluation of PVT collectors, experimentally and numerically. They used phase-change material (paraffin wax) mixed with nano-SiC for cooling of PV module which enhances the output power to 12.7V. They also approximated that the cost of output power would be 0.125$ per KWh 29. AL-Musawi et al. researched on the effect of phase-change material (PCM) and SiO2/water nanofluid on decreasing the temperature of PV module 30.

Sardarabadi et al. in their experimental studied showed that the exergy efficiency of PVT collector escalates compared with a single PV Panel. By utilizing water, TiO2, Al2O3 and ZnO as working fluid, the exergy efficiency of PV module increase to 12.34, 15.93, 18.27 and 15.45%, respectively 31. Alous et al. compared the energy and exergy efficiency of PVT collectors with nanofluids containing multiwalled carbon nanotubes and graphene nanoplatelets and reported that the energy and exergy efficiency of collector with graphene nanoplatelets is higher which the former is 63.1% and the latter is 20.6% 32. Furthermore, Fudholi et al introduced a new theoretical approach to analyzing the exergy and energy efficiency of PVT collectors with TiO2/water nanofluid 33.

Meanwhile, Iyahraja et al. researched on the properties of silver nanofluid with polyvinylpyrrolidone and sodium dodecyl sulfate and study the size of the particle and the surfactant characteristics. They showed that by increment of particle size, the stability would be decreased 34. Koca et al. also studied the properties of silver nanofluid without any surfactant and compare with water 35.

Aslfattahi et al. studied the effect of using MXene based Silicone oil nanofluid to enhance the performance of concentrated photovoltaic thermal collector. They reported that the highest thermal conductivity enhancement is gained to be 64% for 0.1 wt% concentration of silicone oil-MXene nanofluid compared to pure silicone oil at 150 °C. Also, due to the results, the efficiency of CPVT is ascended significantly by use of new nanofluid 36. Furthermore, Abdelrazic et al. investigated the stability and energy performance of water-based MXene nanofluids in hybrid PV/thermal solar systems. They optimized and improved the performance of this type of collector 37.

In this paper, stability, thermo-physical and thermal properties of PVP coated silver nanofluid which was prepared and stabilized in three different volume concentration are investigated, experimentally. Because of some substantial features of silver such as non-exotic and compatibility with environment, alongside with the highest amount of thermal conductivity among metals, silver was chosen as working fluid in this project. Furthermore, this project can be deemed as the first study on this nanofluid to use as working fluid in PVT collectors. The application of this nanofluid can engender higher efficiency for residential application of PVT solar collectors which pave the way of using solar energy in houses in future.

Materials and Methods

Materials and Methods for Preparing Nanofluid

In this study, Silver nanoparticle coated with PVP (US Research Nanomaterials, Inc., USA) has been used as the main particle of deionized water-based nanofluid. The properties of nanoparticles are elaborated in Amongst different processes of preparation of nanofluids, in this research, two steps method have been employed to be used. In his process, nanoparticles with volume fractions of 250, 500 and 1000 ppm are dispersed in deionized water as the fluid. In order to better dispersion of nanoparticles in the base fluid, an Ultrasonic device with power of 400 W (Hielscher Ultrasonic UP400D – Teltow, Germany) has been utilized which is depicted in Figure 2a. The main features of PVP is the avoidance oxidation of silver nanoparticles and also rising the stability which is added 0.2%wt of silver nanoparticle. Accurately weighed PVP-coated silver nanoparticles and surfactants were dispersed in 1000 ml of deionized water to make sample nanofluids. Data for complete agitation of the nanofluid mixture are as follows: 60 min at 50% amplitude using a 400 W, 20 kHz probe. The samples are displayed in Figure 2b and 2c. It is worth to mention that after 15 min the ultrasonic probe was turned off to prevent the increment of nanofluid’s temperature. Table 1.

Figure 2(a).Preparation of samples prior to the test. (b) and (c). Prepared nanofluid samples.

| Properties | Details |

|---|---|

| Appearance/Color | Black |

| Purity | 99.99% |

| APS | 20 mm |

| SSA | 18-22 m2/g |

| True Density | 10.5 g/cm3 |

| Morphology | Spherical |

Method of Properties Analysis

Regarding the essence of nanofluid which is a mixture of nanoparticles and base fluid, thermophysical properties of a nanofluid relates to of its components. Thus, it is truly crucial to identify and study the properties of nanoparticles. In present research, the analysis of nanoparticles and studying their structure have been carried out by using 2 methods: 1-Transmission Electron Microscope (TEM) and 2- X-Ray Diffraction. For the first method, Transmission Electron Microscope – Model: TEM, EM900, Zeiss, Germany with accelerating voltage of 80 KW has been used. Moreover, for assessing the crystal structure of nanoparticles, an X-Ray Diffract meter (EQUINOX 3000, Inel Inc., Artenay, France) with measuring range of angle 5 to 120° has been used.

Stability

The quality of nanoparticle dispersion in the base fluid can be deemed as the most prominent parameters in studying thermophysical properties of nanofluids. Agglomeration and sedimentation phenomena overshadow the nanofluid’s performance as the working fluid engendering prevention of using them in thermal systems. Consequently, the consideration of nanofluid’s stability in design procedures is consequential. Assessing the stability and dispersal of nanofluids can be carried out using several methods. Zeta Potential method has been used here in as the dispersal assessment method. Calculating the zeta potential and particle sizes has been done by using ZEN 3600, Malvern Instruments Ltd., UK. Dynamic Light Scattering (DLS) is a technique which is ideal for the measurement of the size of colloids, nanoparticles and molecules, without requiring agitation to make the sample suitable for analysis. From the size, an estimate of the molecular weight can be made, which has the benefit of being faster to confirm oligomer state than size exclusion chromatography (SEC). While, Electrophoretic Light Scattering (ELS) is based on dynamic light scattering. The frequency shift or phase shift of an incident laser beam depends on the dispersed particles mobility. In the case of dynamic light scattering, Brownian motion causes particle motion. In the case of electrophoretic light scattering, oscillating electric field performs the same function.

Results and Discussion

TEM & X-Ray

(Figure 3)a shows the TEM photo of PVP coated silver nanoparticle. Also, according to X-ray diffraction of silver nanoparticle, a reflection in the XRD pattern of silver nanoparticles at 2-h values of 38.28, 44.45, 64.25 and 77.52 degrees attributed to the 111, 200, 220 and 311 planes of Ag, respectively, showed the structure of crystalline was cubic. The peaks in Figure 3 show that the main composition of nanoparticles was Ag and no peaks of an impurity phase were found in the XRD patterns.

Figure 3(a).Result of nanoparticles TEM analyze, (b). The X-Ray result of nanoparticle that used in this study

Stability

The measurement results of nanoparticle diameters for the 1000 ppm nanofluid sample have been demonstrated in Figure 4. According to figure, the size of nanoparticles has been measured as 82.38 nm.

Figure 4.Result of Zeta sizer test for 1000 ppm sample

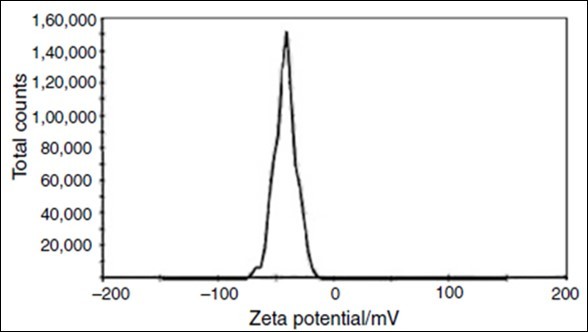

Regarding analyzing zeta potential of nanofluid, the stability boundary of this potential has been determined as 25 mV (negative or positive) 38. Based on the results (Figure 5), PVP coated silver nanofluid’s zeta potential is calculated -41.6 V leading the fact that this nanofluid has an adequate range of stability.

Figure 5.Result of Zeta potential test for 1000 ppm sample

Thermophysical properties of working fluids such as density, specific heat, viscosity and thermal conductivity have striking impact on the performance of PVT collectors. The existence of nanoparticle affects the thermophysical properties of base fluids which the amount of this changes depends on type, dimension and features of nanoparticles 39. Due to the low concentration of nanofluids and also by consideration of permissible amount of zeta potential, it can be concluded that nanoparticles suspend in base fluid for long time and moves with fluid without any slip, continuously. Thus, nanofluids can be heeded as a single phase flow in collector 40.

Density

In this research, Pak Chu equation is utilized to calculate the density of nanofluids 13. (Equation (1))

ρnf = (1-φ)ρf + φρp ….(1)

In Equation (1), φ is volume fraction of nanofluid, ρf and ρp are density of base fluid and PVP coated silver nanoparticles, respectively; and ρnf is density of nanofluid which is demonstrated in Table 2.

Table 2. Density of nanofluids| sample | Volume concentration (ppm) | Density (g/cm3) |

| water | zero | 998.2 |

| Ag1 | 250 | 1000.75 |

| Ag2 | 500 | 1002.51 |

| Ag3 | 1000 | 1007.02 |

Specific Heat Capacity

The specific heat capacity of working fluids having striking impact on thermal performance of PVT collectors can be calculated by equation (2).

…(2)

…(2)

According to the physical properties of base fluid and silver nanoparticle, specific heat capacity of nanofluids are indicated in Table 3.

Table 3. Specific heat capecity of nanofluids at different temperatures (J/Kg.K)| (°C)Temperature | Deionized Water | Ag3 | Ag2 | Ag1 |

| 20 | 4183 | 4135.96 | 4159.35 | 4171.14 |

| 25 | 4181 | 4133.93 | 4157.33 | 4169.13 |

| 30 | 4179 | 4131.89 | 4155.31 | 4167.12 |

| 35 | 4178 | 4130.82 | 4154.28 | 4166.1 |

| 40 | 4179 | 4131.73 | 4155.23 | 4167.08 |

| 45 | 4181 | 4133.61 | 4157.17 | 4169.05 |

| 50 | 4182 | 4134.5 | 4158.12 | 4170.02 |

| 55 | 4183 | 4135.37 | 4159.05 | 4170.99 |

| 60 | 4185 | 4137.23 | 4160.98 | 4172.95 |

The trend of specific heat capacity in terms of temperature for different volume concentration of nanofluids is illustrated in Figure 6. Furthermore, the changes of Cp in terms of volume concentration at 25 and 40 °C are shown in Figure 7.

Figure 6.Specific heat capacity of the nanofluids in terms of temperature

Figure 7.Changing Specific heat capacity in terms of concentration of nanofluids concentration at 25 and 40 °C

As it can be seen in Figure 6 and Figure 7, by growth of volume concentration of nanofluids, the specific heat capacity decrease significantly. Due to noticeable different between the base fluid’s and silver nanoparticle’s heat capacity and also low concentration of nanofluids, the trend of Cp for nanofluids follow the pattern of base fluid’s curve. Thus, the higher concentration of nanofluids, the more decrement is occurred in specific heat capacity. According to the results, the specific heat capacity of 500 and 1000 ppm silver nanofluid decrease compared to the deionized water, which the former is 5% and the latter is 10% lower than base fluid. The Cp of water is 17 times higher than silver, so the more amount of silver nanoparticle the more decrease would be occurred in the specific heat capacity of nanofluid.

Thermal Conductivity

Experimental researches indicates that fluids including nanoparticles, have more thermal conductivity coefficient and lower specific heat capacity than base fluids 41. In current study, transient hot wire method has been utilized for measuring thermal conductivity of nanofluids in temperature range of 25 to 55°C by using KD2 Pro device with TR-1 sensor kit (KD2 Pro, Decagon devices Inc., USA). For each nanofluid sample, 3 separate measurements with 15-minute time intervals have been carried out. Finally, the average value of these 3 measurements has been calculated and reported as thermal conductivity coefficient of samples which are shown in Figure 9 with ± 1% standard deviation.

Nanoparticles decline the time of heat transfer in nanofluids by increasing thermal conductivity and thermal diffusion of them. It is worth to mention that nanoparticles have larger surface area compared to micro particles and other bigger particles which leads to escalate the heat transfer, in this section, the enhancement of thermal conductivity coefficient by increasing the volume fraction of nanofluid and also temperature has been discussed. Thermal conductivity of nanofluids depends on temperature strikingly. To the extent that, by surging the temperature from 25 to 55°C thermal conductivity of base fluid and 1000 ppm silver nanofluid’s growth would be 0.06 and 0.49 W/mK, respectively. By increment of temperature from 25 to 55°C, the amount of K is increased for all samples with different range. The thermal conductivity of water and 1000 ppm PVP coated silver nanofluid are 0.54 and 0.6 W/mK respectively in 25°C. Whereas, these quantity are increased to 0.594 and 1.098 W/mK in 55°C.

Due to the Brownian motions of nanoparticles, the movements of particles are ascended by increasing temperature. While, the viscosity of base fluid decreases facilitating the movements of particles. On the other hand, the number of particles are escalated by increasing the volume fraction of nanofluids. Thus, as it can be seen in Figure 8, the upward trend of thermal conductivity is repeated for all samples, whereas this increment grows with volume concentration and temperature.

Figure 8.Thermal conductivity coefficient changes by temperature for nanofluids and base fluid

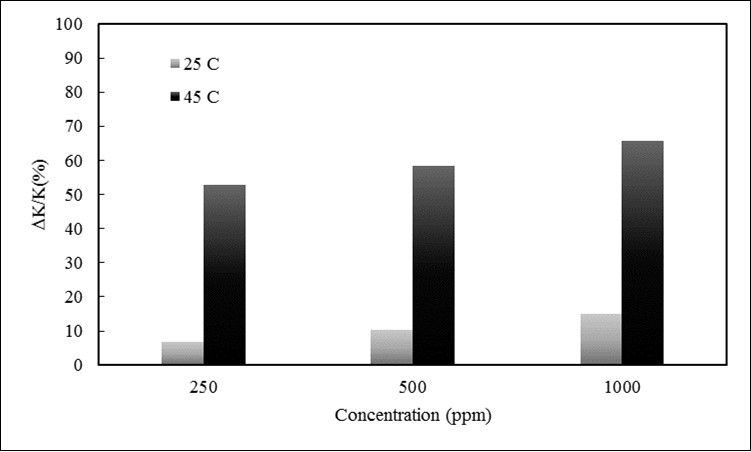

In order to better analyses of thermal conductivity, the increment of thermal conductivity coefficient of nanofluids compared to the base fluid are calculated and demonstrated at 25 and 45°C in Figure 9.

Figure 9.Thermal conductivity coefficient changes by temperature for nanofluids and base fluid

According to Figure 9, the more increment of temperature and concentration, the more escalation is occurred in thermal conductivity of nanofluids compared to the base fluid. At 45°C, thermal conductivity of 1000 ppm silver nanofluid is about more than 70% of base fluid, whereas this ratio is lower than 20% at 25°C.

Based on the results and the trend of thermal properties of PVP coated silver nanfluid, it can be deemed that the power of energy absorption would be increased by the increment of volume concentration of nanofluid. The more escalation of energy absorption, the more thermal and electrical energy will be produced by PVT solar collectors engendering higher efficiency in the same conditions.

Compared to the performance of solar panel module, the more waste heat is transferred from the PV module, since the high capacity of nanofluid can gain more thermal energy which decrease the temperature of PV module and increase the efficiency. The main barrier of high efficiency in PV module is their high temperature which can be solved by applying nanofluids as working fluid in PVT collectors.

Conclusion

Due to inevitable necessity of utilizing renewable energy technologies in installation systems of buildings and also tangible dependency of PVT collectors on the thermal properties of working fluids, the vital properties of PVP-coated silver nanofluid are evaluated experimentally. In this research, nanofluids are prepared in three different volume concentrations and the stability, thermophysical properties and thermal conductivity of them are examined. The following conclusions resulted from this work:

The stability of nanofluids are studied experimentally indicating that the zeta potential of PVP-coated silver nanofluids is -41.6 mV which is acceptable amount.

Because of low volume concentration of nanofluids, density and specific heat capacity of nanofluids in all concentrations have intangible changes compared to the base fluid.

The most prominent feature of nanofluid is thermal conductivity which is analyzed by transient hot wire method. Based on the results, the by ascending temperature and volume concentration of nanofluids, thermal conductivity rises noticeably. To the extent that thermal conductivity of PVP-coated silver nanofluid as about two times more than deionized water at 55 °C.

By consideration of all results and also the amount of thermal conductivity and specific heat capacity, the best concentration which can engender more suitable performance of PVT collector is 1000 ppm PVP coated silver nanofluid. The highest amount of thermal conductivity coefficient is 1.098 which is gained in 55 °C for 1000 ppm sample leading more heat can be conducted from the PV module and more efficiency can be accessed.

References

- 1.Charalambous P, Maidment G G, Kalogirou S A, Yiakoumetti K. (2007) . Photovoltaic thermal (PV/T) collectors: A review, Applied thermal engineering,27(2,3): 275-286.

- 2.Aldubyan M, Chiasson A. (2017) Thermal study of Hybrid Photovoltaic-Thermal (PVT) solar collectors combined with borehole thermal energy storage systems". , Energy Procedia 141, 102-108.

- 3.S A Kalogirou. (2004) Environmental benefits of domestic solar energy systems". , Energy Conversion and Management 45, 3075-3092.

- 4.H K Balotaki, M H Saidi. (2019) Design and Performance of a Novel Hybrid Photovoltaic–Thermal Collector with Pulsating Heat Pipe (PVTPHP)". , Iranian Journal of Science and Technology, Transactions of Mechanical Engineering 43(1), 371-381.

- 5.Trisaksri V, Wongwises S. (2007) Critical review of heat transfer characteristics of nanofluids. , Renewable and Sustainable Energy Reviews 11(3), 512-523.

- 6.Daungthongsuk W, Wongwises S. (2007) critical review of convective heat transfer of nanofluids". , Renewable and Sustainable Energy Reviews 11(5), 797-817.

- 7.Liu Y, Sun G, Wu D, Dong S. (2019) Investigation on the correlation between solar absorption and the size of non-metallic nanoparticles. , Journal of Nanoparticle Research 21(7), 161.

- 8.Sivarathinamoorthy H, Sureshkannan G. (2020) The influence of internal heat storage material and longitudinal fins on a double-pass solar air heater performance. , Journal of Solar Energy Engineering 1-18.

- 9.Aslfattahi N, Saidur R, Arifutzzaman A, Sadri R, Bimbo N et al. (2020) Experimental investigation of energy storage properties and thermal conductivity of a novel organic phase change material/MXene as A new class of nanocomposites. , Journal of Energy Storage 27, 101115.

- 10.Parashar N, Aslfattahi N, S M Yahya, Saidur R. (2020) An artificial neural network approach for the prediction of dynamic viscosity of MXene-palm oil nanofluid using experimental data. , Journal of Thermal Analysis and Calorimetry

- 11.A I Khan, A V. (2019) A review of influence of nanoparticle synthesis and geometrical parameters on thermophysical properties and stability of nanofluids. , Thermal Science and Engineering Progress 11, 334-364.

- 12.Krishna Y, Faizal M, Saidur R, K C Ng, Aslfattahi N. (2020) State-of-the-art heat transfer fluids for parabolic trough collector. , International Journal of Heat and Mass Transfer 152, 119541.

- 13.Karami M, Bahabadi M A Akhavan, Delfani S, Ghozatloo A. (2014) A new application of carbon nanotubes nanofluid as working fluid of low-temperature direct absorption solar collector". , Solar Energy Materials and Solar Cells 121, 114-118.

- 14.Karami M, Raisee M, Delfani S, Bahabadi M A Akhavan, A M Rashidi. (2013) Sunlight absorbing potential of carbon nanoball water and ethylene glycol-based nanofluids. , Optics and Spectroscopy 115(3), 400-405.

- 15.Karami M, M A Akhavan-Behabadi, M Raisee Dehkordi, Delfani S. (2016) Thermo-optical properties of copper oxide nanofluids for direct absorption of solar radiation. , Solar Energy Materials and Solar Cells 144, 136-142.

- 16.Vakili M, Hosseinalipour S, Delfani S, Khosrojerdi S. (2016) Photothermal properties of graphene nanoplatelets nanofluid for low-temperature direct absorption solar collectors. , Solar Energy Materials and Solar Cells 152, 187-191.

- 17.Milanese M, Colangelo G, Cretì A, Lomascolo M, Iacobazzi F et al. (2016) Optical absorption measurements of oxide nanoparticles for application as nanofluid in direct absorption solar power systems–Part II: ZnO. CeO2, Fe2 O3 nanoparticles behavior, Solar Energy Materials and Solar Cells 147, 321-326.

- 18.Menbari A, A, Ghayeb Y. (2016) Experimental investigation of stability and extinction coefficient of Al 2 O 3–CuO binary nanoparticles dispersed in ethylene glycol–water mixture for low-temperature direct absorption solar collectors". , Energy Conversion and Management 108, 501-510.

- 19.T P Otanicar, J S Golden. (2009) Comparative environmental and economic analysis of conventional and nanofluid solar hot water technologies. , Environmental science & technology 43(15), 6082-6087.

- 20.A Z, M, Kadirgama K, Rahman S, M A.Thermal Conductivity and Viscosity of TiO2/MWCNTs (doped 10wt% graphene)-Ethylene Glycol Based Nanofluids for Different Ratio of Nanoparticle.

- 21.S M Hisham, Kadirgama K, Ramasamy Devarajan, R S.. Enhancement of Tribological Behaviour and Thermal Properties of Hybrid Nanocellulose/Copper (II) Oxide Nanolubricant .

- 22.Aste N, Chiesa G, Verri F. (2008) Design, development and performance monitoring of a photovoltaic-thermal (PVT) air collector,". , Renewable energy 33, 914-927.

- 23.Aste N, Leonforte F, C Del Pero. (2015) Design, modeling and performance monitoring of a photovoltaic–thermal (PVT) water collector,". , Solar Energy 112, 85-99.

- 24.J H Lee, S G Hwang, G H Lee. (2019) Efficiency Improvement of a Photovoltaic Thermal (PVT) System Using Nanofluids," Energies. 12(16), 3063.

- 25.Razali N F M, Fudholi A, M H Ruslan, Sopian K. (2019) Electrical characteristic of photovoltaic thermal collector with water-multiwalled carbon nanotube nanofluid flow". , Indonesian Journal of Electrical Engineering and Computer Science (IJEECS) 13, 324.

- 26.Fayaz H, Nasrin R, N A Rahim, Hasanuzzaman M. (2018) Energy and exergy analysis of the PVT system: Effect of nanofluid flow rate,". , Solar Energy 169, 217-230.

- 27.Evola G, Marletta L. (2014) Exergy and thermoeconomic optimization of a water-cooled glazed hybrid photovoltaic/thermal (PVT) collector,". , Solar Energy 107, 12-25.

- 28.Jia Y, Ran F, Zhu C, Fang G. (2020) Numerical analysis of photovoltaic-thermal collector using nanofluid as a coolant,". , Solar Energy 196, 625-636.

- 29.A H, H A Kazem, M T Chaichan, Sopian K. (2019) Experimental investigation of using nano-PCM/nanofluid on a photovoltaic thermal system (PVT): technical and economic study". Thermal Science and Engineering Progress 11, 213-230.

- 30.AL-Musawi A I A, Taheri A, Farzanehnia A, Sardarabadi M, Passandideh-Fard M. (2019) Numerical study of the effects of nanofluids and phase-change materials in photovoltaic thermal (PVT) systems,". , Journal of Thermal Analysis and Calorimetry 137(2), 623-636.

- 31.Sardarabadi M, Hosseinzadeh M, Kazemian A, Passandideh-Fard M. (2017) Experimental investigation of the effects of using metal-oxides/water nanofluids on a photovoltaic thermal system (PVT) from energy and exergy viewpoints". , Energy 138, 682-695.

- 32.Alous S, Kayfeci M, Uysal A. (2019) Experimental investigations of using MWCNTs and graphene nanoplatelets water-based nanofluids as coolants in PVT systems,". , Applied Thermal Engineering 162, 114265.

- 33.Fudholi A, Razali N F M, M H Yazdi, Ibrahim A, M H Ruslan et al. (2019) TiO2/water-based photovoltaic thermal (PVT) collector: Novel theoretical approach". , Energy 183, 305-314.

- 34.Iyahraja S, J S Rajadurai. (2016) Stability of aqueous nanofluids containing PVP-coated silver nanoparticles. , Arabian Journal for Science and Engineering 41(2), 653-660.

- 35.H D Koca, Doganay S, Turgut A. (2017) Thermal characteristics and performance of Ag-water nanofluid: Application to natural circulation loops. , Energy Conversion and Management 135, 9-20.

- 36.Aslfattahi N, Samylingam L, A S, Arifutzzaman A, Saidur R J S E M. (2020) MXene based new class of silicone oil nanofluids for the performance improvement of concentrated photovoltaic thermal collector. Solar Energy Materials and Solar Cells. 211, 110526.

- 37.A S, K H Tan, Aslfattahi N, Arifutzzaman A, Saidur R et al. (2020) Optical, stability and energy performance of water-based MXene nanofluids in hybrid PV/thermal solar systems. , Solar Energy 204, 32-47.

- 38.Yu W, Xie H. (2012) A review on nanofluids: preparation, stability mechanisms, and applications. , Journal of Nanomaterials,1

- 39.Hong T-K, Yang H-S, Choi C. (2005) Study of the enhanced thermal conductivity of Fe nanofluids. , Journal of Applied Physics 97(6), 064311.

Cited by (2)

This article has been cited by 2 scholarly works according to:

Citing Articles:

Applied Sciences (2023) Crossref

J. Pereira, A. Moita, António L. N. Moreira - Applied Sciences (2023) Semantic Scholar

Applied Sciences (2023) OpenAlex